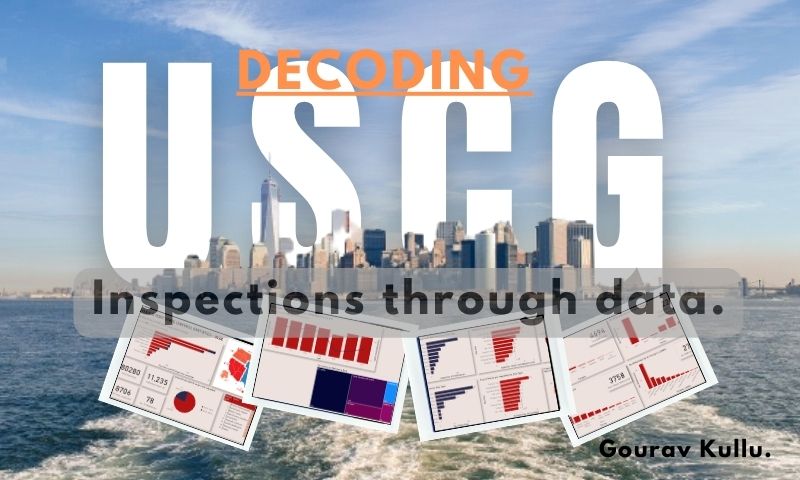

Decoding USCG inspections through data.

As you set sail for the shores of the United States, it's crucial to be well-prepared for the rigorous Port State Control (PSC) inspections conducted by the United States Coast Guard (USCG). In this blog, we’ll delve into the insightful statistics and trends from the USCG inspections for the year 2022 (which is the latest available). By understanding these statistics, you'll gain valuable insights into common deficiencies, areas of focus, and best practices that can help streamline your vessel's preparations for the inspection process and ensure deficiency-free inspection.

Fig.1

The US coast is divided into 9 sectors, as you may see in the image above. According to the 2022 data released by USCG, a total of 80,280 ship visits were made by 11,235 individual vessels in the year 2022. With a maximum number of ship visits of 25,620 in the New Orleans sector to 1,186 ship visits in the Hawaii sector. From the first chart in the above image, it is evident that over 50% of the vessel traffic arrives in Districts 7 and 8 which are New Orleans and Miami. The least traffic is seen in Districts 14 and 17 which are Hawaii and Alaska respectively.

The total number of PSC inspections carried out for the year 2022 was 8,706. Comparing this with the individual ship visits it can be seen that 77.5% of vessels that called US ports were inspected. So, if your vessel is calling the US then there is a 77.5% chance that your vessel will be inspected while a very narrow chance of 23% that your vessel may not face a USCG inspection. One may conclude not all vessels calling US ports get inspected by USCG.

From the table above, Hawaii may have the least ship visits but it certainly has the highest probability of vessel getting inspected. While District 9, Great Lakes, had the least probability of a vessel inspection.

A total of 78 vessels were detained in the year 2022. The maximum detentions came from District 7, Miami, Florida, and zero detentions from District 17 which is Alaska.

Fig-2

A year-on-year comparison of the number of inspections carried out can be seen in Fig 2. Undoubtedly 2020 witnessed the least inspections and also the least number of detentions. However, post-COVID the number of inspections carried out has gone up to pre-COVID levels and so are the detentions which are in an uptrend and indicating to go higher and soon to catch up with the pre-COVID era.

Detentions by Deficiency type: Fire safety systems, Safety management systems, and Lifesaving appliances have been the top 3 deficiencies leading to detentions. These 3 categories together bring forth over 60% of the ship detentions. This clearly shows that the focus of the inspections is on the safety of the ship and the crew.

Fig-3

Inspection with deficiencies by Ship type: Bulk carriers top the list yet again, whether it is in terms of inspections resulting in deficiencies or detentions. However, one should also consider that the maximum number of inspections also happens on bulk carriers. For the year 2022, there were over 2,500 inspections of which 616 inspections resulted with deficiencies and 27 detentions occurred on bulk carriers. Container ships and General dry cargo vessels take the second and third spot. Based on this graph one should not mistake dry cargo vessels being more substandard. We need to find an appropriate ratio or percentage for a better comparison which we’ll see in the further analysis.

Inspection Vs. Inspection with deficiency ratio: When we divide the total number of inspections of a particular type of vessel by number of inspections with deficiency, we obtain a ratio. If the ratio is large it indicates better performance of the category in inspections while a lower value indicates poor performance of the category in inspections. Chemical tankers top the list with a ratio of 6.3, Gas carriers follow with a ratio of 6.0, and the third spot secured by oil tankers with a ratio of 5.1. Passenger ship has a ratio of 1.9 indicating that in every 2 inspections 1 inspection results with a deficiency. The overall average is 4.26.

Avg. deficiency per inspection by ship type: This graph essentially shows if an inspection has to happen what can be the expected number of deficiencies further it has been categorized by ship type. According to the data, Passenger ship has an average deficiency of 3.6 per inspection. This means every time a passenger ship goes for a USCG inspection they can expect 3 to 4 deficiencies. The least being for oil tanker and gas carrier standing at 1.8 and 1.7 respectively. The overall average is seen at 2.29.

Fig-4

No. Of deficiency by category of the convention: As we have seen earlier the maximum number of deficiencies come from fire safety, safety management systems, and lifesaving appliances. Hence it is obvious that the maximum deficiencies are from the SOLAS convention. The same is reflected in this graph. The next two conventions are ILO/MLC and Ship certificates and documents. SOLAS alone contributes to 3,758 deficiencies while ILO has 263 and Ship documents and certificates have 255 deficiencies.

No. Of Deficiencies by Category SOLAS: Further diving deep into SOLAS what we can derive is that Fire safety measures have contributed to 1,504 deficiencies Life-saving appliances with 570 deficiencies and Stability and structure with 420 deficiencies. It indicates that most deficiencies had originated from Chapter 2 and Chapter 3 of SOLAS.

No. Of Deficiencies by Category MARPOL: Although the total MARPOL-related deficiencies were only 228 but still, I have tried to drill down and try to understand the pattern here as it is certainly an important convention. Among the MARPOL-related deficiencies, Annex 1 is the top contributor to deficiencies. Followed by Annex 6 and Annex 5 as seen in the graph above in Fig-4.

No. Of Deficiencies by Category in BWM: Finally, some special mention to the Ballast water management Plan. The total number of deficiencies was 273. The top contributing factor is the ballast water management system (BWMS) with 118 deficiencies, followed by COTP reporting with 44 deficiencies and NBIC reporting with 30 deficiencies. The data suggests that following correct reporting procedures is very important when calling US ports.

So, as you embark on your next voyage to the US, heed the lessons gained from the analysis be vigilant, be prepared, and above all sail with confidence. Please note that the analysis is for the year 2022. A descriptive analysis of past data cannot predict the future precisely, but it certainly can establish certain patterns and trends.

Through this blog, I wish to communicate a few key points:

- Each deficiency is a call to action. Seafarers along with vessel management should work together to maintain the highest standards of safety at sea.

- These inspections, though sometimes daunting, are crucial for ensuring maritime safety and environmental protection.

(If you liked the content and this kind of analysis and visualization. You can learn all of this in our upcoming course Maritime focused Advanced Excel and Power BI. Check out the training to learn more about the course and register.)

Gourav Kullu

With over 21 years of oil tanker experience, I have honed my skills and expertise in navigating the oceans and managing diverse maritime operations.

Experienced marine faculty with 2+ years of teaching expertise in GP Rating, HND Nautical Science, and STCW courses. Committed to creating interactive and practical learning environments for students.

Beyond the waves, I'm a data enthusiast, conducting Power BI courses to bridge the gap between analytics and maritime expertise.

As a driven and dedicated professional, I am equipped with the knowledge, experience, and passion to make a significant impact within the maritime industry.

Leave a comment

View more

Give your career a boost with S&B professional services.

CV Prep/EvaluationMore Jobs

Ship management

Mumbai

Electrical Superintendent

Ports and Pilotage

Mombasa, Kenya

AGM / DGM

Agency and Logistics

Dubai

Director Operations

Interview Prep/Mentoring

Find your polestar with the host of experts available on our platform

Know more